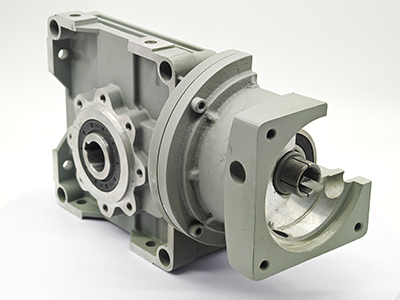

Helical-Hypoid Gear Reducers for Heavy-Duty Applications

The Helical-Hypoid Gear Reducer combines the smooth meshing of helical gearing with the high-torque characteristics of hypoid geometry. This hybrid design delivers high torque density, quiet operation, and a compact right-angle gear drive ideal for heavy-duty equipment. Paired with an MES-Drive Gearbox, you gain reliable speed reduction and long service life in demanding 24/7 operations.

Key Advantages

High torque gearbox performance with excellent load carrying capacity.

Energy-efficient speed reducer design lowers power loss and operating costs.

Low-noise gearbox operation thanks to optimized tooth contact and micro-finishing.

Space-saving 90-degree transmission for compact machinery layouts.

Robust materials, advanced heat treatment, and extended lubrication intervals.

Typical Industrial Applications

Heavy-duty conveyors, bulk material handling, packaging lines, mixers and crushers, steel and metallurgy processes, and automated warehouses all benefit from an industrial helical-hypoid geared motor that balances efficiency and durability.

Selection Tips

Match reducer size and ratio to required output torque and speed, consider duty cycle and ambient conditions, and verify mounting orientation. For precision lines, specify low backlash; for harsh environments, use sealed housings and enhanced IP ratings.

Conclusion

When you need a compact, energy-efficient gearbox that handles shock loads and continuous duty, choose an MES-Drive Helical-Hypoid Gear Reducer. It’s a proven upgrade path for uptime, efficiency, and cost control.

Leave A Reply

Your email address will not be published. Required fiels are marked